About Us

Helping You Tackle Projects That Were Impossible Before.

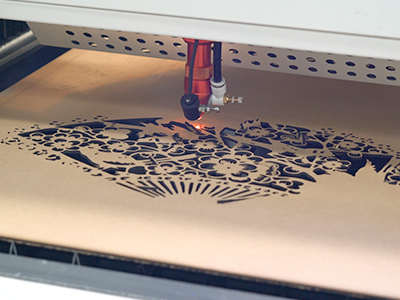

The traditional methods of cutting and manufacturing are slow, costly, and lack customization. Creative Laser Craft Solutions was founded to revolutionize this process by making laser cutting fast, affordable, and tailored to your needs—allowing you to create amazing projects without compromise.

From Tool Room to Industry Innovators

Sanjeev Kumar, our founder, was passionate creator who spent countless hours working on projects in his workshop. He used whatever tools he had at his disposal, but often had to make compromises. When he decided to enhance his projects with custom laser-cut parts, he faced an unexpected challenge

- Local shops were uninterested in small orders

- Nobody had one stop solution for all custom laser cutting solutions

He met with long wait times and high costs, sometimes thousands of rupees for a single part, or the need to order in bulk from overseas. This outdated manufacturing approach was a significant roadblock.

Determined to overcome these hurdles, Sanjeev Kumar decided to find a better way to bring his ideas to life. And so, Creative Laser Craft Solutions was born.

From Side Hustles to Full-Time Success

At Creative Laser Craft Solutions, we are thrilled to support the endeavors of countless engineers, makers, entrepreneurs, designers, and fabricators.

Our clients are turning their side projects into thriving businesses, expanding their capabilities, and tackling bolder ventures.

We provide more than just laser cutting services – we offer the tools and support to make previously impossible projects a reality.

And we couldn't be more excited about that.

Who We Are

At Creative Laser Craft Solutions, we are your go-to experts for all things laser and CNC. We specialize in MDF, acrylic, leather, and fabric laser cutting, as well as laser marking and engraving. Our services extend to 3D CNC cutting and engraving, ensuring every project is executed to perfection. From laser cutting job work and product design to mandir jali cutting and product prototyping, we handle it all with precision and care.Our expertise shines in creating stunning decor items, bespoke name plates, eye-catching neon signs, and personalized and corporate gifts. We excel in picture engraving, architectural model cutting, PVC HDMR wall panels, 3D engraving, and DIY projects. Whatever your laser cutting or CNC needs, Creative Laser Craft Solutions has you covered, delivering quality and creativity every time.

Achievements

Our Business Achievements

Our Team

Head Of Team

Kuldeep Rajput

Supervisor

Raju

Operations

Lets Get In Touch

Stay Connected With Us & Get In Touch

Office Address

Address 1: Office: C-152, 33 feet road, Mahavir Enclave Part-3 New Delhi-110059

Address. 2: CNC Workshop: 13/10, UER 2, Nangli Sakrawati Industrial Area, New Delhi-110043

Email Address

creativelasercraft@gmail.com

Telephone

9910053969

9811644337

We Are Here To Help

All Frequently Asked Question

Yes, we offer shipping services for completed orders. Shipping costs will depend on the size and destination of the order. We will provide shipping options and costs when we confirm your order.

We accept various payment methods, including bank transfers, credit/debit cards, UPI, and cash payments.

Yes, we offer discounts for bulk orders. Please contact us with your order details, and we will provide a customized quote with the applicable discounts.

The maximum thickness we can cut depends on the material, but generally, we can cut up to 25mm for certain materials like acrylic and MDF through CNC cutting technology. Laser cutting has less capacity to cut thick material.

1. Thickness of Material: More the material is thin faster it gets cut. ||||||||||||||||||| 2. Complexity of Designs: Complex designs with many features can slow down the laser cutting process.

We can cut and process more than 50+ Non Metallic materials, Majorly used materials are: 1. Mild Steel 2. Stainless Steel 3. MDF (Medium Density Fibreboard) 4. Acrylic 5. Leather & PU Foam 6. HDHMR Board 7. PVC Board 8. ACP Sheet 9. Birch Ply 10. Cork Sheet 11. Polyester Fabric 12. Sublimation Sheet

The biggest difference between CNC and laser cutting is that a CNC cutter uses a drill bit to cut through material whereas a laser cutter uses a laser beam. Cnc cutters take advantage of the fact that CNC touches the material by drilling into it to remove the material, Cnc cutters can cut thicker materials than laser cutters, Laser cutters, however, are not dependent on the material properties in order to perform a cut (of course, the correct laser beam needs to be used). As such, laser cutters can cut with more precision that cnc cutters including Metal, Acrylic, MDF and Leather etc.

We accept .dxf, ,cdr, svg, .ai file for processing of cutting and engraving.

No Problem! You can connect with our designers and get it made, but that takes time so kindly have sufficient time beforehand. In this fast pace world urgency sucks peace of mind though.

We can cut all kinds of Metallic, Non- Metallic Materials. For eg:- Steel, MS, Acrylic, MDF (medium density fiberboard), HDF, HDHMR, PVC, WPC, ACP Sheets etc.

Laser Cutting is a very fast process when compared to other manufacturing techniques. However, complex designs with many features and engraved designs can slow down the production process. Largely it varies as per laser job which can only be identified by setting and deciding the design and the material used.

Among all production methods, laser cutting is one of the most cost-effective solutions thanks to its speed, accuracy, repeatability and ability to load new and complex design files.

You can navigate through Google maps by clicking on Map section. https://g.co/kgs/C3Q55aD It will navigate you to our Manufacturing unit.